The challenge for apparel manufacturers to satisfy a wide range of consumer demands is unprecedented today. These consumers are diverse in terms of socioeconomics, physiographics, and demographics. Their preferences are difficult to predict. They are also more knowledgeable about the different products and can access it easily. Consumers are also becoming more inclined buy high-fashion, costly items.

Production efficiency

Apparel manufacturers must improve their production efficiency. Because the apparel industry is dependent on human labor and changing fashion trends it is critical to ensure that production planning is in place. Apparel manufacturers must be flexible enough to meet global demands and maintain a short product cycle. In addition to designing new products, apparel companies should assess the efficiency of existing lines, and consider digital technologies that can speed up the product development process from months down to days. Final, critical path analysis plays a crucial role in the planning process.

Although the apparel manufacturing industry is very labor-intensive, it is not impossible to increase production efficiency. To achieve this goal, you need the right tools as well as proper management. EBITDA can rise by up to 35% with an efficiency increase of only 10 to 15%. Moreover, efficiency increases workers' wages and can improve the country's ability to compete in the global market.

Fabric layering

Fabric layering can be used in apparel production. It involves placing a layer of pre-made patterns on top. The pattern can be made manually or with a plotter. The pattern components are placed in the markers. These are then cut using a straight or other method.

The fabric is evenly distributed during this process. You can either lay the fabric in a stack or superimpose layers with the markings. The maximum cut width is the fabric width less the needle marks and the selvedge. The fabric utilization refers to the amount of fabric used. There are two types of layout: half-garment and whole-garment. Half-garment lie involves only laying fabric on one side, while whole garment lay involves covering the entire garment piece with fabric. However, whole-garment lay consumes more fabric.

Cutting

The cutting process uses cutting blades to reduce a piece of fabric to a smaller size. Fabric can cost between 60 and 70 percent of a garment's price. It is crucial that every inch be used. It is important to use every inch of fabric when making apparel.

Spreading the fabric across a large table is one of the steps in cutting fabric. In mass production, the fabric is spread over a number layers. Based on how many garments are to be made and how thick the fabric is, the cutting master will determine the amount of layers that should be spread over a garment. After the fabric has been spread it is measured to determine the maximum cutting width.

Pressing

In the manufacture of apparel, pressing is an important step. It controls the appearance of garments and helps them to maintain their comfort. This is done in a factory. A press can be automated or manually operated. Software can be used to control the automation level. Programming a press can allow it to follow specific instructions. An automated pressing system can reduce human error in apparel manufacturing factories. The increased number of fabric and fiber varieties will require more precise temperature and pressure control.

The process of pressing involves heating the fibers of the garment. The shape of the garment is stabilized with the softened fibres. To prevent damaging the yarn or fibres, choose the appropriate temperature.

Minimum order quantity

When sourcing for a clothing manufacturer, you should be aware of the Minimum Order Quantity, or MOQ, of the factory you are looking at. Without this minimum order quantity, many garment factories won't make your garments. The MOQ is dependent on the technical characteristics of your designs and varies from one factory to another. Some factories only accept orders of a few hundred items, while others require orders of thousands.

A minimum order quantity is essential for all manufacturers, particularly those that deal in bulk goods. The MOQ helps manufacturers remain profitable. It also helps businesses decide whether they want to buy small quantities of goods or if they are looking for large orders. This is especially important with custom orders.

FAQ

What are the essential elements of running a logistics firm?

You need to have a lot of knowledge and skills to manage a successful logistic business. For clients and suppliers to be successful, you need to have excellent communication skills. You need to understand how to analyze data and draw conclusions from it. You must be able manage stress and pressure under pressure. In order to innovate and create new ways to improve efficiency, creativity is essential. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

You should also be organized and efficient to meet tight deadlines.

What skills should a production planner have?

Production planners must be flexible, organized, and able handle multiple tasks. Communication skills are essential to ensure that you can communicate effectively with clients, colleagues, and customers.

What is the difference between Production Planning and Scheduling?

Production Planning (PP), also known as forecasting and identifying production capacities, is the process that determines what product needs to be produced at any particular time. Forecasting demand is one way to do this.

Scheduling is the process of assigning specific dates to tasks so they can be completed within the specified timeframe.

How can manufacturing prevent production bottlenecks?

To avoid production bottlenecks, ensure that all processes run smoothly from the moment you receive your order to the time the product ships.

This includes planning for both capacity requirements and quality control measures.

This can be done by using continuous improvement techniques, such as Six Sigma.

Six Sigma Management System is a method to increase quality and reduce waste throughout your organization.

It seeks to eliminate variation and create consistency in your work.

What is the importance of automation in manufacturing?

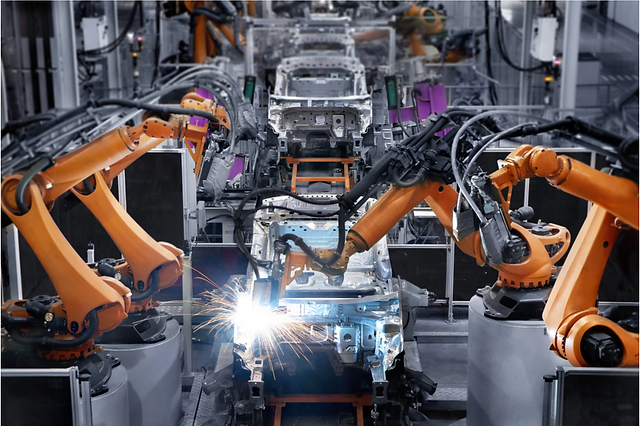

Automation is essential for both manufacturers and service providers. Automation allows them to deliver services quicker and more efficiently. It helps them to lower costs by reducing human errors, and improving productivity.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to use the Just-In Time Method in Production

Just-in-time is a way to cut costs and increase efficiency in business processes. It's a way to ensure that you get the right resources at just the right time. This means that you only pay the amount you actually use. Frederick Taylor, a 1900s foreman, first coined the term. Taylor observed that overtime was paid to workers if they were late in working. He then concluded that if he could ensure that workers had enough time to do their job before starting to work, this would improve productivity.

The idea behind JIT is that you should plan ahead and have everything ready so you don't waste money. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. You will have the resources and people to solve any problems you anticipate. This will prevent you from spending extra money on unnecessary things.

There are many types of JIT methods.

-

Demand-driven JIT: This is a JIT that allows you to regularly order the parts/materials necessary for your project. This will enable you to keep track of how much material is left after you use it. You'll also be able to estimate how long it will take to produce more.

-

Inventory-based: This is a type where you stock the materials required for your projects in advance. This allows you predict the amount you can expect to sell.

-

Project-driven : This is a method where you make sure that enough money is set aside to pay the project's cost. When you know how much you need, you'll purchase the appropriate amount of materials.

-

Resource-based: This is the most common form of JIT. You assign certain resources based off demand. If you have many orders, you will assign more people to manage them. If you don’t have many orders you will assign less people to the work.

-

Cost-based: This is similar to resource-based, except that here you're not just concerned about how many people you have but how much each person costs.

-

Price-based pricing: This is similar in concept to cost-based but instead you look at how much each worker costs, it looks at the overall company's price.

-

Material-based - This is a variant of cost-based. But instead of looking at the total company cost, you focus on how much raw material you spend per year.

-

Time-based: This is another variation of resource-based JIT. Instead of focusing on the cost of each employee, you will focus on the time it takes to complete a project.

-

Quality-based JIT: This is another variation of resource based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based JIT: This is the latest form of JIT. In this instance, you are not concerned about the product's performance or meeting customer expectations. Instead, your goal is to add value to the market.

-

Stock-based: This inventory-based approach focuses on how many items are being produced at any one time. This method is useful when you want to increase production while decreasing inventory.

-

Just-in time (JIT), planning: This is a combination JIT/supply chain management. This refers to the scheduling of the delivery of components as soon after they are ordered. It's important because it reduces lead times and increases throughput.