If you're interested in a supply chain management career, you can start by researching industries that offer good opportunities. It is important to research the industry to see how many people are employed in it, what skills they have, and what jobs are available. You can also connect with human resource professionals and recruiters when you are looking for work. Depending upon your goals, you might also consider joining a professional group to learn about certification programs.

Supply chain management is an exciting field that requires a variety of skills. It may seem difficult and complex, but it's also extremely rewarding. You will have lots of opportunities and flexibility.

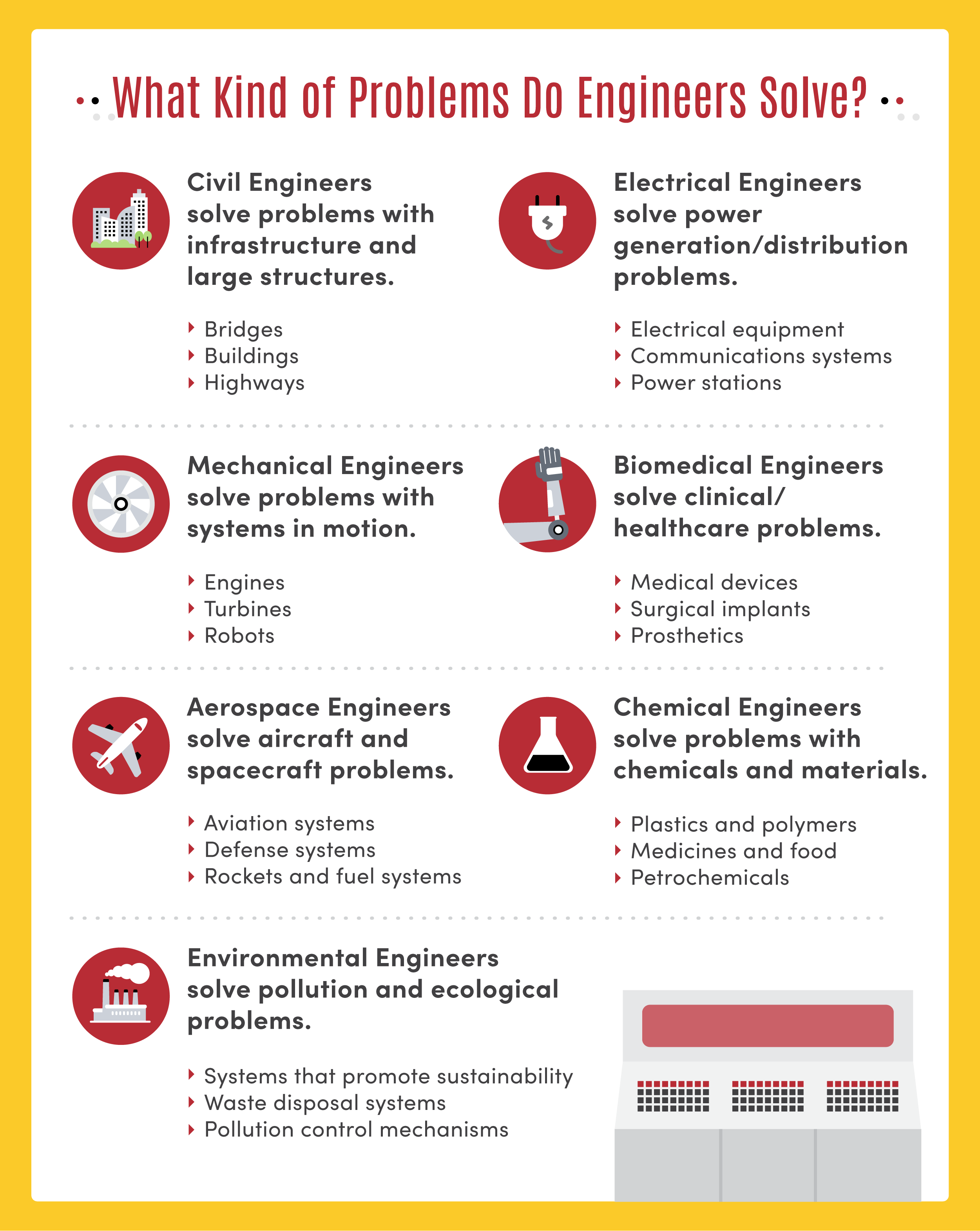

Logistics and supply chain managers must have skills in project management, critical thinking, interpersonal communication, sustainability, and organizational leadership. In addition, they must be able to effectively communicate with stakeholders at all levels of an organization. They must also know how to implement new technologies and understand international regulations.

Companies today look at their supply chains from a larger perspective. This means that not every supply chain model is right for you. One company might have multiple product areas that you can work on while another family-owned business may offer fewer career advancement options. Your satisfaction can also be affected greatly by the company's size.

To get started, it's important to create a strong network. Make friends with supply chain management professionals in HR, and learn more about the industries that you are interested. Once you have a strong network, it's possible to search for a job in supply chain. Most supply chain jobs are competitive, and you'll have to show that you have the requisite expertise and experience.

Supply chain management is an unpredictable, fast-paced field. You need to be flexible and able to quickly solve problems. By working through problems as quickly as possible, you can prevent disruptions to your supply chain and safeguard the goals of your organization.

You will be involved in data collection and organization as part of your supply chain career. This knowledge is vital for making decisions and allocating staff resources effectively. Data collection and management are essential for supporting all aspects of customer service.

The supply chain manager should also be capable of managing projects and managing finances. While they might be tasked with managing multiple projects at once, they should be able to prioritize them and decide which ones are most important. They'll need the ability to weigh both the benefits and disadvantages of each decision.

Supply chain management is a career that can be pursued by those who wish to work in retail, healthcare or transportation. The salary and job opportunities for these positions are varied. To get a job within each industry, however, you will need to have some professional experience.

There are many jobs in supply chain management, which is a rapidly growing field. You can use what you love about working with people to make a career out of this fast-paced field.

FAQ

Why is logistics important in manufacturing

Logistics is an integral part of every business. They are essential to any business's success.

Logistics plays a significant role in reducing cost and increasing efficiency.

What is the difference between manufacturing and logistics

Manufacturing is the process of creating goods from raw materials by using machines and processes. Logistics covers all aspects involved in managing supply chains, including procurement and production planning. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

What does manufacturing industry mean?

Manufacturing Industries are those businesses that make products for sale. These products are sold to consumers. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. They create goods from raw materials, using machines and various other equipment. This includes all types if manufactured goods.

What are the responsibilities of a manufacturing manager

A manufacturing manager must make sure that all manufacturing processes run smoothly and effectively. They must also be alert to any potential problems and take appropriate action.

They must also be able to communicate with sales and marketing departments.

They should also be knowledgeable about the latest trends in the industry so they can use this information for productivity and efficiency improvements.

How can manufacturing overproduction be reduced?

In order to reduce excess production, you need to develop better inventory management methods. This would reduce time spent on activities such as purchasing, stocking, and maintaining excess stock. This could help us free up our time for other productive tasks.

You can do this by adopting a Kanban method. A Kanbanboard is a visual tool that allows you to keep track of the work being done. In a Kanban system, work items move through a sequence of states until they reach their final destination. Each state represents a different priority level.

When work is completed, it can be transferred to the next stage. A task that is still in the initial stages of a process will be considered complete until it moves on to the next stage.

This allows work to move forward and ensures that no work is missed. Managers can view the Kanban board to see how much work they have done. This information allows them to adjust their workflow based on real-time data.

Lean manufacturing is another option to control inventory levels. Lean manufacturing emphasizes eliminating waste in all phases of production. Anything that doesn't add value to the product is considered waste. Here are some examples of common types.

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Materials in excess

These ideas can help manufacturers improve efficiency and reduce costs.

Why automate your warehouse

Modern warehouses have become more dependent on automation. E-commerce has increased the demand for quicker delivery times and more efficient processes.

Warehouses should be able adapt quickly to new needs. They must invest heavily in technology to do this. The benefits of automating warehouses are numerous. Here are some of the reasons automation is worth your investment:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Safety enhancements

-

Eliminates bottlenecks

-

Allows companies scale more easily

-

Workers are more productive

-

Provides visibility into everything that happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

Ensures quality products are delivered on time

-

Human error can be eliminated

-

This helps to ensure compliance with regulations

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to use lean manufacturing in the production of goods

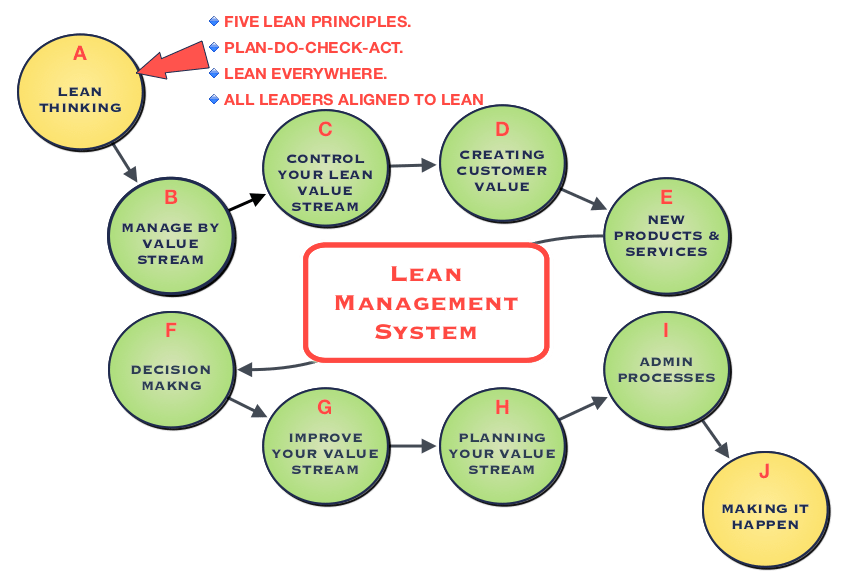

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was first developed in Japan in the 1970s/80s by Taiichi Ahno, who was awarded the Toyota Production System (TPS), award from KanjiToyoda, the founder of TPS. Michael L. Watkins published the "The Machine That Changed the World", the first book about lean manufacturing. It was published in 1990.

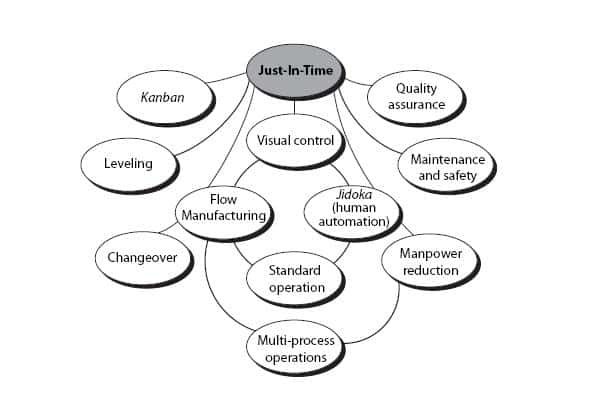

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It emphasizes reducing defects and eliminating waste throughout the value chain. Just-in-time (JIT), zero defect (TPM), and 5S are all examples of lean manufacturing. Lean manufacturing is about eliminating activities that do not add value, such as inspection, rework, and waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Lean manufacturing can be found in many industries. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define Value- Identify the added value your company brings to society. What makes you stand out from your competitors?

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Although lean manufacturing isn't a new concept in business, it has gained popularity due to renewed interest in the economy after the 2008 global financial crisis. Many businesses have adopted lean manufacturing techniques to help them become more competitive. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing, which has many benefits, is now a standard practice in the automotive industry. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

Lean manufacturing can be applied to almost every aspect of an organization. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three main types:

-

Just-in Time Manufacturing (JIT), also known as "pull system": This form of lean manufacturing is often referred to simply as "pull". JIT refers to a system in which components are assembled at the point of use instead of being produced ahead of time. This approach is designed to reduce lead times and increase the availability of components. It also reduces inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. Repairing a part that is damaged during assembly should be done, not scrapping. This is true even for finished products that only require minor repairs prior to shipping.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous improvement involves continuous improvement of processes and people as well as tools.