Orlando has a large number of logistics companies. They provide services for both big and small businesses. For those looking to launch a new career, this sector has a range of positions, ranging from entry-level to management roles paying more than $100,000 a year.

Orlando offers a variety of jobs related to logistics, such as truck drivers, warehouse assistants, and shipping clerks. These jobs will allow you to gain experience across a range of areas.

Orlando has an industry worth $1.5 billion that is dedicated to moving goods. As a result of its central location, the city has several major shipping centres.

These hubs enable companies in Orlando to reach out to a variety of clients. These hubs also make it easy for companies to ship cargo from all over the country.

If you want to work in logistics, there are a few things you'll need to know about the field. To begin with, you will need to be able to manage large volumes of cargo. This includes negotiating contracts, and making sure that the supplies are given to the correct people when they need them.

Know about the security and safety measures of the cargos you transport. Orlando's leading logistics firms offer advanced tracking and security technology, along with cargo certifications.

It is also important to consider the company’s customer service and reputation before deciding on them for your logistics. By reading customer reviews, talking to representatives and reviewing feedback from others you can get a good idea of the company.

Logistics companies that are the best in Orlando should have a solid reputation, and be known for their reliability and high-quality service. The logistics company should be able provide accurate information to their clients and offer reliable shipping and deliveries at competitive rates.

AIT, Roadrunner Transportation Systems and Worldwide Express are a few of the best Orlando-based logistics companies. These companies all focus on helping small- to medium size businesses ship smarter.

These companies provide a variety of services such as inventory management, supply chain management and freight forwarding. The companies offer a 24-hour customer service so you are taken care of even if your work hours have ended.

Orlando shipping services should be able do any job that you ask of them, from local warehousing to international transportation. They should also be equipped with the necessary staff and equipment to handle all types of moves, no matter how large or little.

Orlando's large population and its strong labor force make it a great destination for the logistics sector. The area has easy access to air, rail, and sea transportation. This is an ideal location to locate a logistics firm that needs to be at the heart of the most popular tourist destinations.

FAQ

What are the 7 Rs of logistics?

The 7R's of Logistics is an acronym for the seven basic principles of logistics management. It was developed and published by the International Association of Business Logisticians in 2004 as part of the "Seven Principles of Logistics Management".

The following letters make up the acronym:

-

Responsible - ensure that actions are in compliance with legal requirements and do not cause harm to others.

-

Reliable: Have faith in your ability or the ability to honor any promises made.

-

Be responsible - Use resources efficiently and avoid wasting them.

-

Realistic – Consider all aspects, including cost-effectiveness as well as environmental impact.

-

Respectful - treat people fairly and equitably.

-

You are resourceful and look for ways to save money while increasing productivity.

-

Recognizable: Provide customers with value-added service

What are the logistics products?

Logistics are the activities involved in moving goods from point A to point B.

They include all aspects of transport, including packaging, loading, transporting, unloading, storing, warehousing, inventory management, customer service, distribution, returns, and recycling.

Logisticians ensure that products reach the right destination at the right moment and under safe conditions. Logisticians assist companies in managing their supply chains by providing information such as demand forecasts, stock levels and production schedules.

They keep track and monitor the transit of shipments, maintain quality standards, order replenishment and inventories, coordinate with suppliers, vendors, and provide support for sales and marketing.

What's the difference between Production Planning & Scheduling?

Production Planning (PP), also known as forecasting and identifying production capacities, is the process that determines what product needs to be produced at any particular time. Forecasting and identifying production capacity are two key elements to this process.

Scheduling is the process that assigns dates to tasks so they can get completed within a given timeframe.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to Use the Just In Time Method in Production

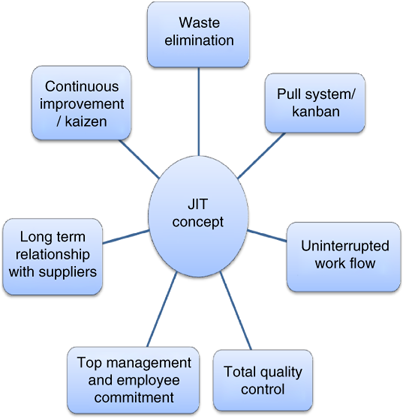

Just-in-time is a way to cut costs and increase efficiency in business processes. It's the process of obtaining the right amount and timing of resources when you need them. This means that only what you use is charged to your account. Frederick Taylor, a 1900s foreman, first coined the term. He noticed that workers were often paid overtime when they had to work late. He decided that workers would be more productive if they had enough time to complete their work before they started to work.

JIT is a way to plan ahead and make sure you don't waste any money. The entire project should be looked at from start to finish. You need to ensure you have enough resources to tackle any issues that might arise. You will have the resources and people to solve any problems you anticipate. This will ensure that you don't spend more money on things that aren't necessary.

There are different types of JIT methods:

-

Demand-driven: This is a type of JIT where you order the parts/materials needed for your project regularly. This will let you track the amount of material left over after you've used it. This will let you know how long it will be to produce more.

-

Inventory-based: This is a type where you stock the materials required for your projects in advance. This allows you predict the amount you can expect to sell.

-

Project-driven: This approach involves setting aside sufficient funds to cover your project's costs. You will be able to purchase the right amount of materials if you know what you need.

-

Resource-based JIT: This is the most popular form of JIT. Here you can allocate certain resources based purely on demand. For example, if there is a lot of work coming in, you will have more people assigned to them. You'll have fewer orders if you have fewer.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based: This is a variant of cost-based. However, instead of focusing on the individual workers' costs, this looks at the total price of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based: Another variation of resource-based JIT. Instead of focusing solely on the amount each employee costs, focus on how long it takes for the project to be completed.

-

Quality-based JIT is another variant of resource-based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based JIT: This is the latest form of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, you focus on the added value that you provide to your market.

-

Stock-based: This is an inventory-based method that focuses on the actual number of items being produced at any given time. This method is useful when you want to increase production while decreasing inventory.

-

Just-in time (JIT), planning: This is a combination JIT/supply chain management. It's the process of scheduling delivery of components immediately after they are ordered. It's important as it reduces leadtimes and increases throughput.