What is supply chains management? The supply chain management process is cross-functional and focuses on the management relationships throughout the entire supply network. Supply chain management helps improve business performance by improving operational and financial performance. This article will discuss the basics of supply chains management and how it can enhance your organization. Let's get started! What is supply-chain management? Why is supply management so important? Here are a few examples to show how it can be beneficial for your business.

Management of relationships within the supply chain is called supply chain management.

Companies that produce and sell products need to consider how to obtain raw materials, produce parts, and distribute finished goods. The physical flow or goods is created by suppliers and then goes through different steps to reach a manufacturer, distributor and retailer before reaching the end consumer. Certain supply chains skip certain steps, but the physical items must be moved from one point to another, be stored for a period of time, and be delivered to the end customer. This requires organization and planning.

A successful supply chain management strategy requires integration of all business functions. For example, suppliers and vendors need clear communication. Information sharing allows both sides to understand each other's expectations, reduce costs, improve quality, and helps them communicate clearly. Collaboration across the supply chain improves communication and collaboration, which in turn benefits both sides. The customer should be informed about the company's processes and the vendor must be prepared to ship emergency materials. Lead times are particularly critical when a company is selling perishable goods.

It is a cross-functional business process

There are many cross-functional factors that need to be considered when a company is looking at its supply chain. Suppliers must be able deliver goods on-time to ensure a successful supply network. This is why it is important to coordinate with them. Companies can avoid many problems by following the steps described in Supply Chain Management. Companies will be able to improve their efficiency and save money by following these steps.

In addition to understanding the interdependencies of the supply chain, management needs to work toward increasing the profitability of the entire system. It is crucial to create guidelines that will allow everyone to reap the benefits from improved processes. Sometimes, the improvement of the process may not be visible to all parties. If the value is not captured it could be deemed invalid.

It lowers operating costs

Streamlining your ordering processes is one of best ways to reduce operating expenses. Your employees are less likely to be confused by multiple requisitions and order too much product if you use one software platform. You can also reduce your operating expenses by setting up an approvals procedure to limit how many goods you order. A streamlined software system can help you avoid confusion and errors, monitor your inventory and order only what you need. It will also allow you to stop shipments being made if you are not required.

One way to cut operating costs is to improve the communication between warehouse employees. You should first examine your current workflow and identify any bottlenecks. Consolidating or using dedicated transport services can help reduce transportation costs. Operating costs will drop dramatically if you can do this. In addition to reducing transportation costs, it will also help you get your products to customers faster.

It improves the financial position

Many ways supply chain management can increase a business’s financial performance. Supply chain management is a way to lower production costs and reap the rewards of variable costs. Profit margins can be increased by being able to control costs. Another benefit is to improve cash flow. A faster delivery of products to the customer can help it invoice its customers earlier, reducing the need to purchase expensive building space. In addition, a better supply chain reduces the cost of fixed assets.

The Statement on Shareholders’ Equity (SSE), which summarizes ownership in a company, is a crucial financial statement. Improving a firm's supply chain can increase after-tax cash flow by approximately 8.5%. By improving supply chain performance, a company can reduce its costs by as much as 10%, while increasing its customer satisfaction. A company that improves its supply chain management can reduce costs by as much as 10% while increasing customer satisfaction. This will lead to higher operational efficiencies and consequently, greater profits.

FAQ

Is there anything we should know about Manufacturing Processes prior to learning about Logistics.

No. You don't have to know about manufacturing processes before learning about logistics. However, knowing about manufacturing processes will definitely give you a better understanding of how logistics works.

Are there ways to automate parts of manufacturing?

Yes! Yes! Automation has existed since ancient times. The Egyptians discovered the wheel thousands and years ago. Robots are now used to assist us in assembly lines.

There are many uses of robotics today in manufacturing. They include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Manufacturing can also be automated in many other ways. For example, 3D printing allows us to make custom products without having to wait for weeks or months to get them manufactured.

What type of jobs is there in logistics

Logistics can offer many different jobs. Some examples are:

-

Warehouse workers – They load, unload and transport pallets and trucks.

-

Transport drivers - These are people who drive trucks and trailers to transport goods or perform pick-ups.

-

Freight handlers: They sort and package freight in warehouses.

-

Inventory managers - They oversee the inventory of goods in warehouses.

-

Sales representatives - They sell products.

-

Logistics coordinators – They plan and coordinate logistics operations.

-

Purchasing agents: They are responsible for purchasing goods and services to support company operations.

-

Customer service agents - They answer phone calls and respond to emails.

-

Shipping clerks: They process shipping requests and issue bills.

-

Order fillers: They fill orders based off what has been ordered and shipped.

-

Quality control inspectors: They inspect outgoing and incoming products for any defects.

-

Others – There are many other types available in logistics. They include transport supervisors, cargo specialists and others.

What is the role and responsibility of a Production Planner?

Production planners ensure all aspects of the project are delivered within time and budget. They also ensure the quality of the product and service meets the client's requirements.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

How to use Lean Manufacturing in the production of goods

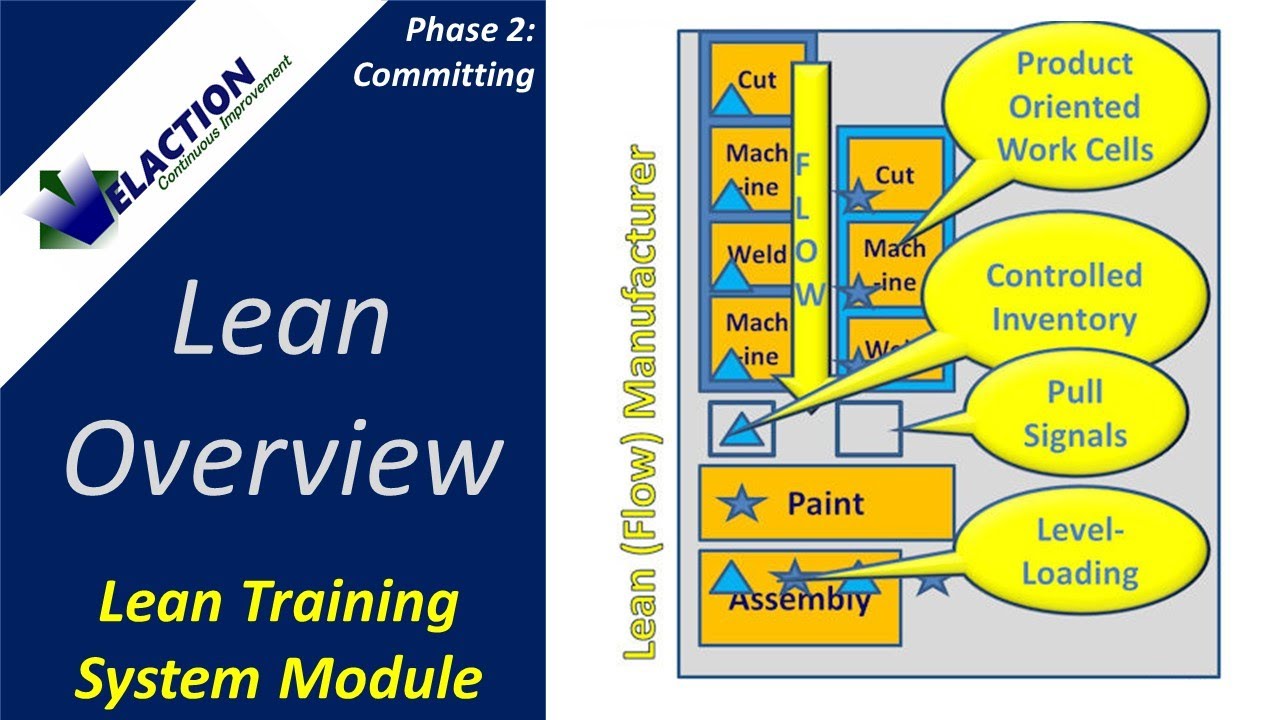

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It emphasizes eliminating waste and defects throughout the value stream. Just-in-time (JIT), zero defect (TPM), and 5S are all examples of lean manufacturing. Lean manufacturing seeks to eliminate non-value added activities, such as inspection, work, waiting, and rework.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Lean manufacturing practices are widespread in many industries. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Five principles are the basis of lean manufacturing:

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce waste - Get rid of any activity that does not add value to the supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Building Relationships – Establish personal relationships with both external and internal stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many businesses are now using lean manufacturing to improve their competitiveness. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing is becoming a popular practice in automotive. It has many advantages. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

It can be applied to any aspect of an organisation. However, it is particularly useful when applied to the production side of an organization because it ensures that all steps in the value chain are efficient and effective.

There are three types principally of lean manufacturing:

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT means that components are assembled at the time of use and not manufactured in advance. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. It is better to repair a part than have it removed from the production line if it needs to be fixed. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous improvement refers to continuous improvement of processes as well people and tools.