Advanced manufacturing is where companies use innovative technologies to produce better products and processes. These technologies are known as advanced, cutting-edge and innovative. These technologies are becoming more common in companies. Robotics and material deposition are some of these technologies. Find out more about these technologies.

Additive manufacturing

Many businesses see additive manufacturing as the future of manufacturing. This type involves additive manufacturing technologies also known as 3D printers. This type is flexible and offers lower inventory costs. This method of manufacturing reduces the need to import labor intensive parts and components.

The speed and flexibility of manufacturing has been greatly improved by advances in additive manufacturing technology. They enable businesses to quickly respond to supply-chain disruptions. They can produce custom parts in hours or days. This process is especially valuable in industries that experience supply-chain problems. Advanced manufacturing is capable of producing parts with complex geometries.

A manufacturer can also make very small quantities. This can be used, for example, to create custom dental appliances. This process allows the creation of complex structures like internal heat channels. Advanced manufacturing by additive manufacturing can also be used to reduce inventory and create specialized parts. It can reduce materials costs up to ninety percent while reducing energy consumption by as much as half.

Robotics

Most industrial producers are keen to use advanced robotics in their manufacturing processes. They are not satisfied with the performance or progress they have made. Many of them cite the high costs and limitations of current technology as barriers to broader deployment. They lack key enablers for fully deploying advanced robotics at their factories.

To effectively integrate advanced robotics, manufacturers must evaluate their system architecture. These systems need to include infrastructure, analytics and data management. These capabilities will allow companies to choose strategic robotics suppliers. These partners will be able to help the company choose which processes and technologies are most suitable for their business. In the case of robotics, this can be accomplished with the use of simulation models.

Advanced robotics is rapidly changing across many industries. Robotic automation can be applied in many areas, such as aerospace, medical and automotive manufacturing. This technology has made manufacturing more efficient. Advanced robotic automation not only reduces labor costs but also saves energy because it works 24 hours a days and doesn't require lights.

Material deposition

In the field of advanced manufacturing, material deposition is an important technique. The process involves using a combination of laser beams and arc plasma energies to deposit thin films of a material on a target. Typically, wire and powder are used as substrates. Deposition is done in an inert atmosphere or vacuum. Other energy sources may also be used.

Plasma metal deposition, which utilizes a plasma source as a method to deposit metals, is one of most promising direct-energy techniques. The process can be used with wire, powder, and both as a feedstock. It can also produce large, complex components. This process offers a lower machining time and shorter lead times.

This process can be applied for ceramics and polymers as well as metals. Metals are typically used in wire and powder forms.

FAQ

How can manufacturing excess production be decreased?

Better inventory management is key to reducing excess production. This would reduce the time needed to manage inventory. This could help us free up our time for other productive tasks.

A Kanban system is one way to achieve this. A Kanbanboard is a visual tool that allows you to keep track of the work being done. In a Kanban system, work items move through a sequence of states until they reach their final destination. Each state is assigned a different priority.

When work is completed, it can be transferred to the next stage. But if a task remains in the beginning stages it will stay that way until it reaches its end.

This allows you to keep work moving along while making sure that no work gets neglected. With a Kanban board, managers can see exactly how much work is being done at any given moment. This data allows them adjust their workflow based upon real-time data.

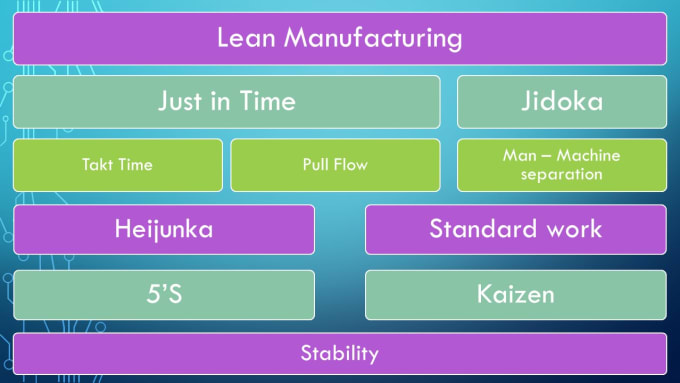

Lean manufacturing can also be used to reduce inventory levels. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Anything that does nothing to add value to a product is waste. There are several types of waste that you might encounter:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Material surplus

These ideas can help manufacturers improve efficiency and reduce costs.

Why automate your warehouse

Automation has become increasingly important in modern warehousing. Increased demand for efficient and faster delivery has resulted in a rise in e-commerce.

Warehouses should be able adapt quickly to new needs. To do so, they must invest heavily in technology. Automating warehouses has many benefits. These are some of the benefits that automation can bring to warehouses:

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Boosts safety

-

Eliminates bottlenecks

-

This allows companies to scale easily

-

Makes workers more efficient

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

Quality products delivered on time

-

Eliminates human error

-

Assure compliance with regulations

Can we automate some parts of manufacturing?

Yes! Yes! Automation has existed since ancient times. The wheel was invented by the Egyptians thousands of years ago. Nowadays, we use robots for assembly lines.

In fact, there are several applications of robotics in manufacturing today. These include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that produce products

Automation could also be used to improve manufacturing. 3D printing is a way to make custom products quickly and without waiting weeks or months for them to be manufactured.

How can we improve manufacturing efficiency?

First, identify the factors that affect production time. Then we need to find ways to improve these factors. You can start by identifying the most important factors that impact production time. Once you have identified the factors, then try to find solutions.

What does it mean to warehouse?

Warehouses and storage facilities are where goods are kept before being sold. It can be either an indoor or outdoor space. It may also be an indoor space or an outdoor area.

What is the responsibility of a logistics manager?

A logistics manager makes sure that all goods are delivered on-time and in good condition. This is achieved by using their knowledge and experience with the products of the company. He/she should also ensure enough stock is available to meet demand.

What is production planning?

Production Planning involves developing a plan for all aspects of the production, including scheduling, budgeting, casting, crew, location, equipment, props, etc. It is important to have everything ready and planned before you start shooting. It should also contain information on achieving the best results on set. This includes information on shooting times, locations, cast lists and crew details.

First, you need to plan what you want to film. You might have an idea of where you want to film, or you may have specific locations or sets in mind. Once you have identified your locations and scenes it's time to begin figuring out what elements you will need for each one. Perhaps you have decided that you need to buy a car but aren't sure which model. You could look online for cars to see what options are available, and then narrow down your choices by selecting between different makes or models.

After you've found the perfect car, it's time to start thinking about adding extras. What about additional seating? Maybe you need someone to move around in the back. You may want to change the interior's color from black or white. These questions will help determine the look and feel you want for your car. Also, think about what kind of shots you would like to capture. Do you want to film close-ups, or wider angles? Maybe you want to show the engine and the steering wheel. These details will help identify the exact car you wish to film.

Once you have made all the necessary decisions, you can start to create a schedule. You can use a schedule to determine when and where you need it to be shot. Every day will have a time for you to arrive at the location, leave when you are leaving and return home when you are done. This way, everyone knows what they need to do and when. It is possible to make arrangements in advance for additional staff if you are looking to hire. You don't want to hire someone who won't show up because he didn't know.

It is important to calculate the amount of filming days when you are creating your schedule. Some projects are quick and easy, while others take weeks. You should consider whether you will need more than one shot per week when creating your schedule. Multiplying takes in the same area will result both in increased costs and a longer time. If you are unsure if you need multiple takes, it is better to err on the side of caution and shoot fewer takes rather than risk wasting money.

Budget setting is another important aspect in production planning. You will be able to manage your resources if you have a realistic budget. It is possible to reduce the budget at any time if you experience unexpected problems. It is important to not overestimate how much you will spend. You'll end up with less money after paying for other things if the cost is underestimated.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to use the Just-In Time Method in Production

Just-in-time (JIT) is a method that is used to reduce costs and maximize efficiency in business processes. It allows you to get the right amount resources at the right time. This means you only pay what you use. The term was first coined by Frederick Taylor, who developed his theory while working as a foreman in the early 1900s. He noticed that workers were often paid overtime when they had to work late. He then concluded that if he could ensure that workers had enough time to do their job before starting to work, this would improve productivity.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. The entire project should be looked at from start to finish. You need to ensure you have enough resources to tackle any issues that might arise. If you expect problems to arise, you will be able to provide the necessary equipment and personnel to address them. This way, you won't end up paying extra money for things that weren't really necessary.

There are many JIT methods.

-

Demand-driven JIT: This is a JIT that allows you to regularly order the parts/materials necessary for your project. This will allow for you to track the material that you have left after using it. This will allow to you estimate the time it will take for more to be produced.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows you to forecast how much you will sell.

-

Project-driven : This is a method where you make sure that enough money is set aside to pay the project's cost. If you know the amount you require, you can buy the materials you need.

-

Resource-based JIT is the most widespread form. This is where you assign resources based upon demand. You might assign more people to help with orders if there are many. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based: This approach is very similar to resource-based. However, you don't just care about the number of people you have; you also need to consider how much each person will cost.

-

Price-based pricing: This is similar in concept to cost-based but instead you look at how much each worker costs, it looks at the overall company's price.

-

Material-based: This is very similar to cost-based but instead of looking at total costs of the company you are concerned with how many raw materials you use on an average.

-

Time-based JIT: This is another variant of resource-based JIT. Instead of focusing only on how much each employee is costing, you should focus on how long it takes to complete your project.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of thinking about the cost of each employee or the time it takes to produce something, you focus on how good your product quality.

-

Value-based JIT is the newest form of JIT. You don't worry about whether the products work or if they meet customer expectations. Instead, your focus is on the value you bring to the market.

-

Stock-based: This inventory-based approach focuses on how many items are being produced at any one time. This is used to increase production and minimize inventory.

-

Just-in time (JIT), planning: This is a combination JIT/supply chain management. It is the process of scheduling components' delivery as soon as they have been ordered. It is essential because it reduces lead-times and increases throughput.