Manufacturing Phoenix, an Arizona company, provides a variety of products to the federal governments. It also offers similar products for individual and commercial clients. Its dedicated facility allows all production to take place under one roof, with resources within a few feet of each other. The company also provides employment opportunities for disabled people for over 40 year. Its manufacturing division employs 70 people.

Honeywell Aerospace

The Phoenix area is home to Honeywell Aerospace, an aerospace company that develops innovative transportation solutions. Its products and services improve flight safety, make vehicles more fuel-efficient, and improve runway traffic. Its products are used in nearly every commercial airliner. Honeywell Aerospace was also instrumental in the development and production of 2001: A Space Odyssey. Honeywell Aerospace also manufactures systems for the International Space Station.

Honeywell created a Phoenix, Arizona reactive metal-alloy additive manufacturing facility in 2016. The facility converted an existing flame spray facility into a production line for parts made from titanium and aluminum alloys. By 2017, Honeywell plans to begin producing parts made of Inconel 718 in this facility. The facility was built by Honeywell, which has invested more than $25,000,000.

Raytheon Technologies Corp.

Raytheon Technologies Corp., a multinational defense and aerospace conglomerate, is headquartered in Arlington Virginia. The company is one of the largest manufacturers of military equipment in the world. It manufactures aircraft, missiles and rockets. Raytheon is not only a major aerospace and defense producer, but also develops advanced technologies that can be used commercially.

Raytheon has an extensive history in both the aerospace and defense industries. For example, 27.4% of net sales are made by Raytheon's Aerial Navigation Systems division. It also makes mechanical and electric systems for airplanes.

Benchmark Electronics

Benchmark Electronics is a contract electronics manufacturing company based in Tempe, Arizona. The Phoenix-based ODM company employs over 13,000 people worldwide. The company operates offices in Tempe Marketplace, Scottsdale, as well as Tempe Marketplace. Gayla Delly was recently promoted to CEO.

Vertically integrated engineering and manufacturing services are offered by the Phoenix manufacturing facility. Its capabilities are embedded electronics design and microwave/RF components. In addition, the company offers aftermarket solutions. It serves a wide variety of customers within the defense, industrial and commercial aerospace markets.

FAQ

What is production planning?

Production Planning involves developing a plan for all aspects of the production, including scheduling, budgeting, casting, crew, location, equipment, props, etc. This document ensures that everything is prepared and available when you are ready for shooting. It should also provide information about how best to produce the best results while on set. This information includes locations, crew details and equipment requirements.

First, you need to plan what you want to film. You might have an idea of where you want to film, or you may have specific locations or sets in mind. Once you have determined your scenes and locations, it is time to start figuring out the elements that you will need for each scene. One example is if you are unsure of the exact model you want but decide that you require a car. You could look online for cars to see what options are available, and then narrow down your choices by selecting between different makes or models.

After you've found the perfect car, it's time to start thinking about adding extras. What about additional seating? Maybe you need someone to move around in the back. Perhaps you would like to change the interior colour from black to white. These questions can help you decide the right look for your car. Another thing you can do is think about what type of shots are desired. What type of shots will you choose? Maybe you want to show your engine or the steering wheel. This will allow you to determine the type of car you want.

Once you have established all the details, you can create a schedule. The schedule will show you when to begin shooting and when to stop. A schedule for each day will detail when you should arrive at the location and when you need leave. Everyone knows exactly what they should do and when. Hire extra staff by booking them ahead of time. It is not worth hiring someone who won’t show up because you didn’t tell him.

You will need to factor in the days that you have to film when creating your schedule. Some projects only take one or two days, while others may last weeks. You should consider whether you will need more than one shot per week when creating your schedule. Multiplying takes in the same area will result both in increased costs and a longer time. If you are unsure if you need multiple takes, it is better to err on the side of caution and shoot fewer takes rather than risk wasting money.

Budgeting is another crucial aspect of production plan. A realistic budget will help you work within your means. Keep in mind that you can always reduce your budget if you face unexpected difficulties. It is important to not overestimate how much you will spend. If you underestimate how much something costs, you'll have less money to pay for other items.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

What skills do production planners need?

Being a production planner is not easy. You need to be organized and flexible. Communication skills are essential to ensure that you can communicate effectively with clients, colleagues, and customers.

Is it possible to automate certain parts of manufacturing

Yes! Yes. The Egyptians invented the wheel thousands of years ago. Today, robots assist in the assembly of lines.

There are many uses of robotics today in manufacturing. These include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that make products

Automation can be applied to manufacturing in many other ways. 3D printing, for example, allows us to create custom products without waiting for them to be made.

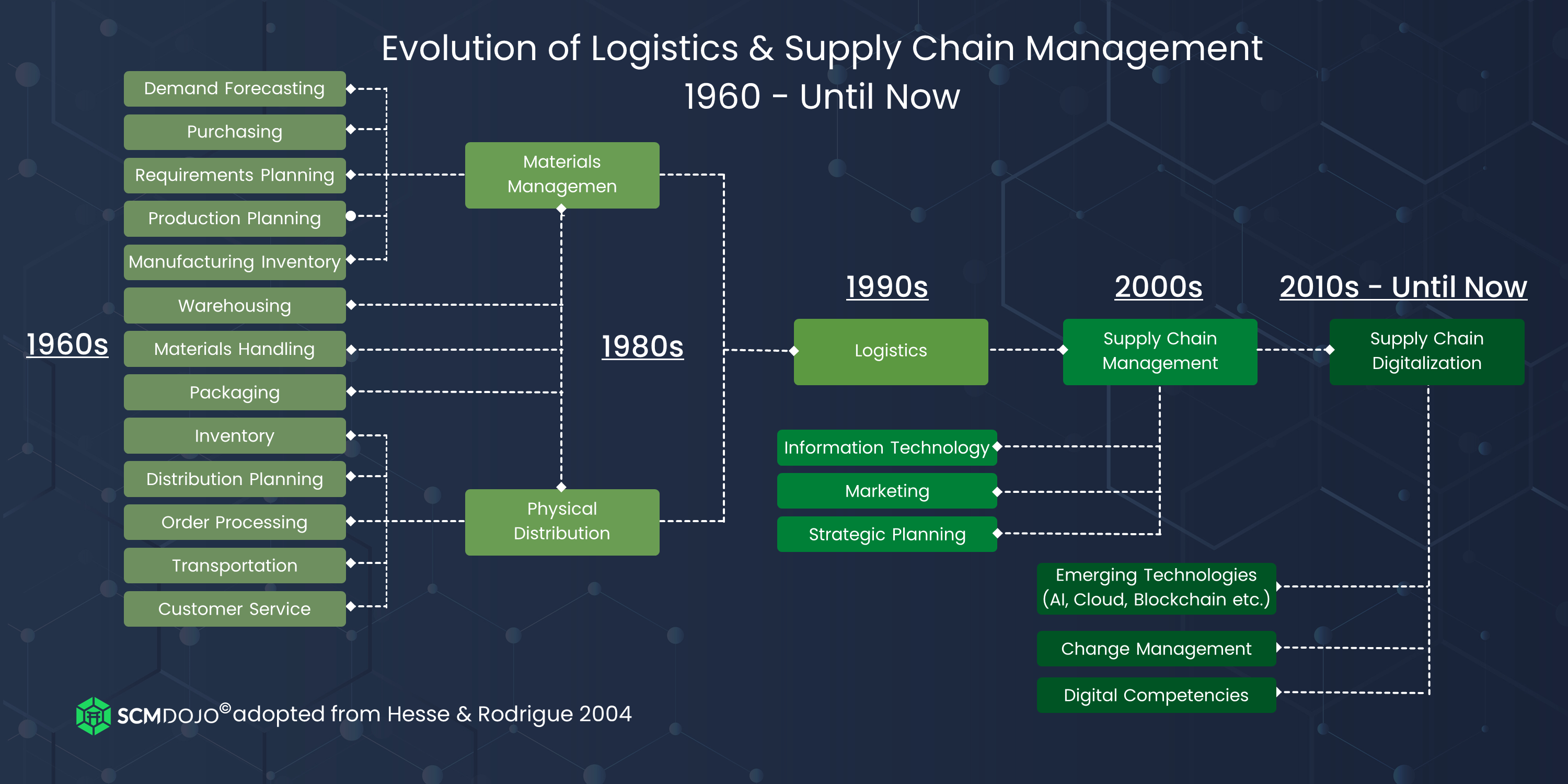

What are the products and services of logistics?

Logistics involves the transportation of goods from point A and point B.

They include all aspects of transport, including packaging, loading, transporting, unloading, storing, warehousing, inventory management, customer service, distribution, returns, and recycling.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. Logisticians help companies improve their supply chain efficiency by providing information about demand forecasts and stock levels, production schedules, as well as availability of raw materials.

They coordinate with vendors and suppliers, keep track of shipments, monitor quality standards and perform inventory and order replenishment.

What are the 4 types manufacturing?

Manufacturing refers the process of turning raw materials into useful products with machines and processes. It involves many different activities such as designing, building, testing, packaging, shipping, selling, servicing, etc.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to use lean manufacturing in the production of goods

Lean manufacturing (or lean manufacturing) is a style of management that aims to increase efficiency, reduce waste and improve performance through continuous improvement. It was developed in Japan during the 1970s and 1980s by Taiichi Ohno, who received the Toyota Production System (TPS) award from TPS founder Kanji Toyoda. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes the elimination of defects and waste throughout the value stream. Just-in-time (JIT), zero defect (TPM), and 5S are all examples of lean manufacturing. Lean manufacturing is about eliminating activities that do not add value, such as inspection, rework, and waiting.

In addition to improving product quality and reducing costs, lean manufacturing helps companies achieve their goals faster and reduces employee turnover. Lean Manufacturing is one of the most efficient ways to manage the entire value chains, including suppliers and customers as well distributors and retailers. Many industries worldwide use lean manufacturing. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Five fundamental principles underlie lean manufacturing.

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce waste - Get rid of any activity that does not add value to the supply chain.

-

Create Flow - Ensure work moves smoothly through the process without interruption.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many companies have adopted lean manufacturing methods to increase their marketability. Many economists believe lean manufacturing will play a major role in economic recovery.

With many benefits, lean manufacturing is becoming more common in the automotive industry. These include higher customer satisfaction, lower inventory levels, lower operating expenses, greater productivity, and improved overall safety.

The principles of lean manufacturing can be applied in almost any area of an organization. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three types principally of lean manufacturing:

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. It is better to repair a part than have it removed from the production line if it needs to be fixed. This is true even for finished products that only require minor repairs prior to shipping.

-

Continuous Improvement (CI): CI aims to improve the efficiency of operations by continuously identifying problems and making changes in order to eliminate or minimize waste. Continuous Improvement involves continuous improvement of processes.