Industrial engineering technicians use their knowledge of mathematics and engineering to determine and improve the way a business runs. This includes developing blueprints for machinery, analyzing statistical data and designing procedures. The skilled industrial engineer will help management make more efficient decisions.

An industrial engineer technician's typical tasks include performing motion and time studies to increase productivity, evaluating performance, and implementing changes. They might also be requested to analyze safety and industrial health data.

Other technical tasks include preparing graphs and diagrams to illustrate the flow of a process. They also perform a variety of tests on products to ensure that they meet quality standards.

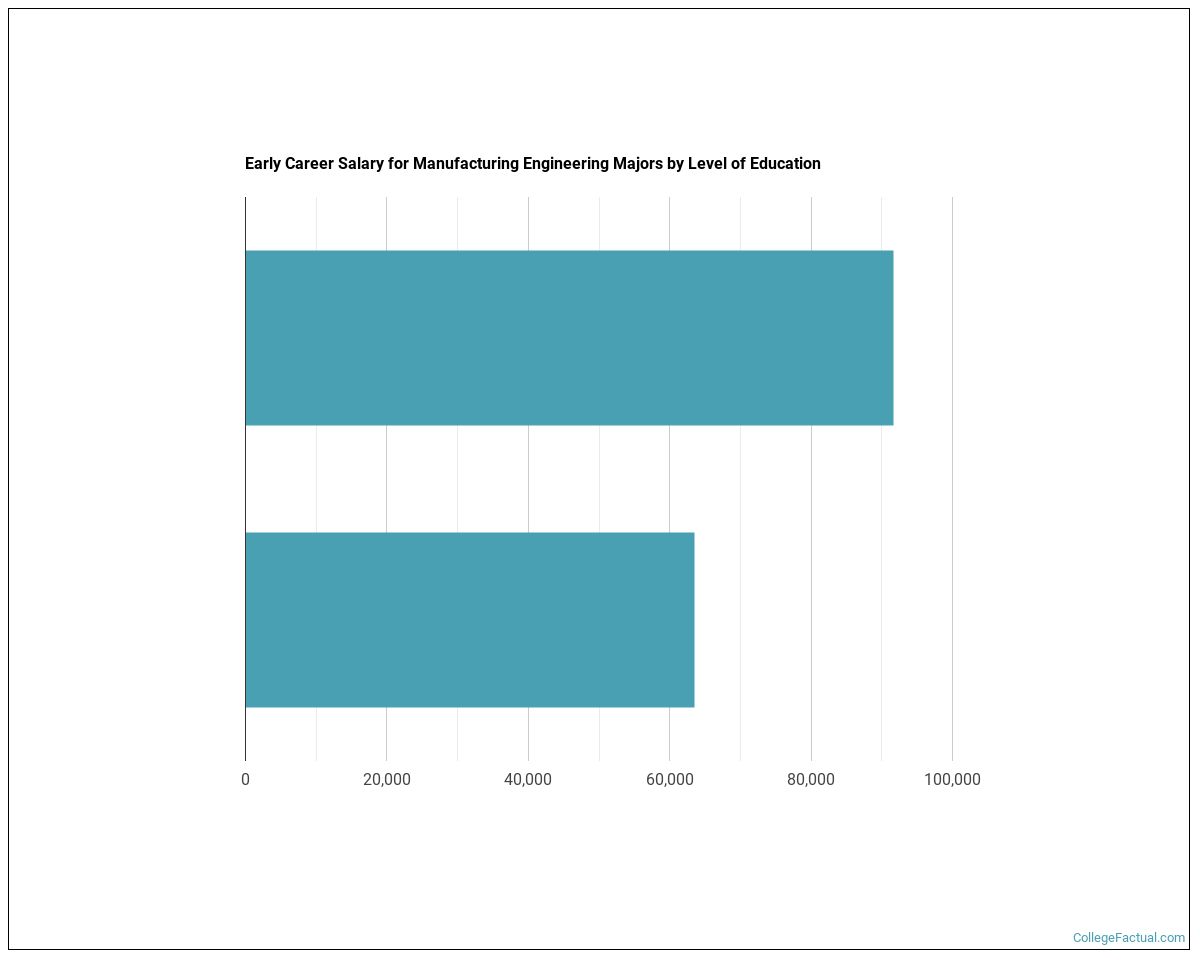

Some of the most popular job functions of an industrial engineer include: planning workflow, analyzing production costs, gauging prototypes, assessing equipment capacities, and developing efficient operating procedures. These engineers can be found in many industries such as aerospace, pharmaceuticals and electronics, as well as food and agriculture. Most work full-time. The average annual salary for these workers is $53,000, although those with more education and experience might be able to make a better living.

Industrial engineers do not need any specific degrees. It is important to have strong math skills and a keen eye for detail. They should also be able communicate with and work with employees and observe the workplace processes.

An industrial engineer technician who is skilled in recognizing the key factors will ensure the most efficient workflow. They must also be able recognize the importance of reducing waste materials and avoiding unproductive practices. As a result, they are able to find ways to implement improvements in the workplace, and to save the organization money in the long run.

They are likely to be the first to test new ideas in their company. One of the most common ways to do this is through a strategic outline. It's similar to putting together pieces of a huge puzzle.

Another important function of an industrial engineering technician is the improvement of the quality of the produced output. While the number of jobs will be decreased by the increasing automation of industries, the role of industrial engineering technicians will be bolstered by a growing focus on cost control.

An engineer might conduct a time-and-motion study to determine the duration of a task and determine the best method to measure its performance. This study could be used by engineers to establish a standard production level. These results will then be used to make improvements to the way an operation is run.

Many universities, including Liberty University offer an industrial engineering program that offers students a range of courses. They include basic machinist skills as well as motor controls, hydraulics, self-management, and hydraulics. The program helps students learn how to work together and problem solve.

FAQ

What are my options for learning more about manufacturing

Hands-on experience is the best way to learn more about manufacturing. You can read books, or watch instructional videos if you don't have the opportunity to do so.

How can excess manufacturing production be reduced?

It is essential to find better ways to manage inventory to reduce overproduction. This would reduce the amount of time spent on unnecessary activities such as purchasing, storing, and maintaining excess stock. This will allow us to free up resources for more productive tasks.

A Kanban system is one way to achieve this. A Kanbanboard is a visual tool that allows you to keep track of the work being done. Kanban systems allow work items to move through different states until they reach their final destination. Each state has a different priority level.

If work is moving from one stage to the other, then the current task can be completed and moved on to the next. But if a task remains in the beginning stages it will stay that way until it reaches its end.

This allows you to keep work moving along while making sure that no work gets neglected. Managers can see how much work has been done and the status of each task at any time with a Kanban Board. This allows them to adjust their workflows based on real-time information.

Lean manufacturing, another method to control inventory levels, is also an option. Lean manufacturing focuses on eliminating waste throughout the entire production chain. Waste includes anything that does not add value to the product. Some common types of waste include:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Overstock materials

These ideas can help manufacturers improve efficiency and reduce costs.

How can manufacturing efficiency improved?

The first step is to identify the most important factors affecting production time. Then we need to find ways to improve these factors. You can start by identifying the most important factors that impact production time. Once you've identified them all, find solutions to each one.

What does manufacturing mean?

Manufacturing Industries are companies that manufacture products. These products are sold to consumers. These companies use a variety processes such as distribution, retailing and management to accomplish their purpose. They make goods from raw materials with machines and other equipment. This includes all types of manufactured goods, including food items, clothing, building supplies, furniture, toys, electronics, tools, machinery, vehicles, pharmaceuticals, medical devices, chemicals, and many others.

What is the responsibility of a manufacturing manager?

The manufacturing manager should ensure that every manufacturing process is efficient and effective. They should also be aware of any problems within the company and act accordingly.

They must also be able to communicate with sales and marketing departments.

They should be informed about industry trends and be able make use of this information to improve their productivity and efficiency.

What is the difference in Production Planning and Scheduling, you ask?

Production Planning (PP) refers to the process of determining how much production is needed at any given moment. This is done through forecasting demand and identifying production capacities.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

Can we automate some parts of manufacturing?

Yes! Yes. The Egyptians created the wheel thousands years ago. Today, robots assist in the assembly of lines.

Actually, robotics can be used in manufacturing for many purposes. They include:

-

Line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Manufacturing could also benefit from automation in other ways. 3D printing, for example, allows us to create custom products without waiting for them to be made.

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to Use Just-In-Time Production

Just-in time (JIT), is a process that reduces costs and increases efficiency in business operations. It's the process of obtaining the right amount and timing of resources when you need them. This means that you only pay for what you actually use. The term was first coined by Frederick Taylor, who developed his theory while working as a foreman in the early 1900s. He saw how overtime was paid to workers for work that was delayed. He realized that workers should have enough time to complete their jobs before they begin work. This would help increase productivity.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. The entire project should be looked at from start to finish. You need to ensure you have enough resources to tackle any issues that might arise. You'll be prepared to handle any potential problems if you know in advance. This will prevent you from spending extra money on unnecessary things.

There are several types of JIT techniques:

-

Demand-driven JIT: This is a JIT that allows you to regularly order the parts/materials necessary for your project. This will allow you to track how much material you have left over after using it. It will also allow you to predict how long it takes to produce more.

-

Inventory-based : You can stock the materials you need in advance. This allows you to forecast how much you will sell.

-

Project-driven: This approach involves setting aside sufficient funds to cover your project's costs. When you know how much you need, you'll purchase the appropriate amount of materials.

-

Resource-based: This is the most common form of JIT. You allocate resources based on the demand. You will, for example, assign more staff to deal with large orders. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based: This is very similar to cost-based, except that instead of looking at how much each individual worker costs, you look at the overall price of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based: This is another variation of resource-based JIT. Instead of worrying about how much each worker costs, you can focus on how long the project takes.

-

Quality-based: This is yet another variation of resource-based JIT. Instead of thinking about the cost of each employee or the time it takes to produce something, you focus on how good your product quality.

-

Value-based JIT: One of the most recent forms of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, you are focused on adding value to the marketplace.

-

Stock-based is an inventory-based system that measures the number of items produced at any given moment. It's useful when you want maximum production and minimal inventory.

-

Just-in-time (JIT) planning: This is a combination of JIT and supply chain management. It's the process of scheduling delivery of components immediately after they are ordered. It's important because it reduces lead times and increases throughput.