Journal impact factors

The Journal Impact Factors in Supply Chain Management are an effective tool for comparing the relative influence of supply-chain management journals. These factors were calculated using data from 10 leading academic journals in supply chain management and the ISI Web of Science. The results allow us to compare and contrast the relative influence of journals and their authors in the field.

Journal impact factors can be used to evaluate a journal's quality. A journal that has a high ranking will likely be high-quality because it attracts high quality research. Journal impact factors are calculated based on the number of citations received by a journal and the importance of related journals. Emerald Group Publishing Ltd. is the Journal's publisher. This publishing company is based in the United Kingdom.

Scope of the journal

The scope of journal supply chain management covers a variety of different topics, including inventory management, transportation, and logistics. Its purpose is to offer a forum for research-based knowledge in these areas. These articles are welcome to be published in the journal. But, it doesn't mean all articles should be published in the journal.

SCMij is an international journal that publishes research in supply chain management. It offers a platform for discussing theoretical and empirical research. Submissions are welcome from scholars, practitioners, students, and others.

Editorial board

A journal's Editorial Board is an organization that reviews the quality of scientific publications. The Board's members are renowned scientists representing different areas of knowledge. The Board guarantees confidentiality of manuscript data and is bound by an editorial code of ethics. The journal is accessible through major search engines, and is already registered in several international scientific databases.

The Journal of Supply Chain Management Editorial Board is made up of experts that focus on supply chain management, logistics, and procurement. Every article submitted for publication is peer-reviewed to ensure that it is relevant and practical.

Article authors published in the journal

Submissions to the Journal of Supply Chain Management are welcome from all supply chain, logistics, procurement professionals. The journal publishes original research as well as review articles on the subject of supply chain management. Your articles should be at most three thousand words long, and you must discuss innovative techniques or ways to solve problems.

Articles can be submitted online. They can either be submitted in plain text or as separate files that include illustrations. Authors need to ensure that all contact details are correct. Articles should include current address and e mail. The journal charges no fees for publication and submission.

Number of articles published in the journal each year

The Journal of Supply Chain Management publishes articles from several journals. High h-index indicates high productivity and high citation impact. The International Standard Serial Number of the journal is 15232409 (total ISSN).

This journal publishes articles from academics and practitioners working in the field of supply chain management. The journal's articles are thought-provoking on supply chain operations. It also publishes columns by supply chain experts and industry analysts. It also publishes case stories of companies as well as their supply chains.

FAQ

What are the responsibilities for a manufacturing manager

Manufacturing managers must ensure that manufacturing processes are efficient, effective, and cost-effective. They must also be alert to any potential problems and take appropriate action.

They should also learn how to communicate effectively with other departments, including sales and marketing.

They should be informed about industry trends and be able make use of this information to improve their productivity and efficiency.

What are the goods of logistics?

Logistics refers to all activities that involve moving goods from A to B.

These include all aspects related to transport such as packaging, loading and transporting, storing, transporting, unloading and warehousing inventory management, customer service. Distribution, returns, recycling are some of the options.

Logisticians ensure that the right product reaches the right place at the right time and under safe conditions. Logisticians help companies improve their supply chain efficiency by providing information about demand forecasts and stock levels, production schedules, as well as availability of raw materials.

They monitor shipments in transit, ensure quality standards, manage inventories, replenish orders, coordinate with suppliers and other vendors, and offer support services for sales, marketing, and customer service.

What skills is required for a production planner?

Being a production planner is not easy. You need to be organized and flexible. It is also important to be able communicate with colleagues and clients.

What are manufacturing and logistic?

Manufacturing is the production of goods using raw materials. Logistics encompasses the management of all aspects associated with supply chain activities such as procurement, production planning, distribution and inventory control. It also includes customer service. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

How does manufacturing avoid bottlenecks in production?

The key to avoiding bottlenecks in production is to keep all processes running smoothly throughout the entire production cycle, from the time you receive an order until the time when the product ships.

This includes planning to meet capacity requirements and quality control.

Continuous improvement techniques like Six Sigma are the best way to achieve this.

Six Sigma Management System is a method to increase quality and reduce waste throughout your organization.

It is focused on creating consistency and eliminating variation in your work.

Why automate your warehouse

Modern warehousing has seen automation take center stage. E-commerce has brought increased demand for more efficient and quicker delivery times.

Warehouses need to adapt quickly to meet changing needs. Technology investment is necessary to enable warehouses to respond quickly to changing demands. Automation warehouses can bring many benefits. Here are some benefits of investing in automation

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Safety Boosts

-

Eliminates bottlenecks

-

Companies can scale up more easily

-

Makes workers more efficient

-

It gives visibility to everything that happens inside the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Reducing downtime and increasing uptime

-

Quality products delivered on time

-

Removing human error

-

Helps ensure compliance with regulations

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

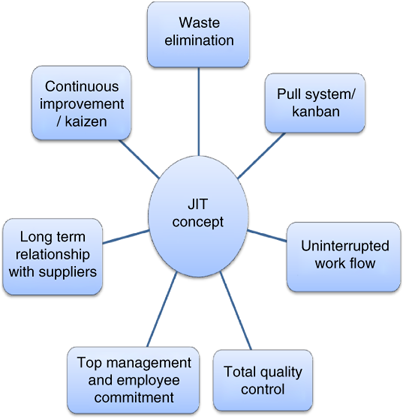

How to use the Just In-Time Production Method

Just-intime (JIT), a method used to lower costs and improve efficiency in business processes, is called just-in-time. It's the process of obtaining the right amount and timing of resources when you need them. This means that your only pay for the resources you actually use. The term was first coined by Frederick Taylor, who developed his theory while working as a foreman in the early 1900s. He noticed that workers were often paid overtime when they had to work late. He decided that workers would be more productive if they had enough time to complete their work before they started to work.

JIT is an acronym that means you need to plan ahead so you don’t waste your money. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. This will prevent you from spending extra money on unnecessary things.

There are many JIT methods.

-

Demand-driven: This JIT is where you place regular orders for the parts/materials that are needed for your project. This will allow for you to track the material that you have left after using it. You'll also be able to estimate how long it will take to produce more.

-

Inventory-based: This allows you to store the materials necessary for your projects in advance. This allows you to predict how much you can expect to sell.

-

Project-driven: This means that you have enough money to pay for your project. You will be able to purchase the right amount of materials if you know what you need.

-

Resource-based JIT is the most widespread form. Here you can allocate certain resources based purely on demand. You will, for example, assign more staff to deal with large orders. If you don't receive many orders, then you'll assign fewer employees to handle the load.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based: This is a variant of cost-based. However, instead of focusing on the individual workers' costs, this looks at the total price of the company.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based: This is another variation of resource-based JIT. Instead of worrying about how much each worker costs, you can focus on how long the project takes.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based: This is one of the newest forms of JIT. This is where you don't care about how the products perform or whether they meet customers' expectations. Instead, you are focused on adding value to the marketplace.

-

Stock-based: This is an inventory-based method that focuses on the actual number of items being produced at any given time. This method is useful when you want to increase production while decreasing inventory.

-

Just-in-time (JIT) planning: This is a combination of JIT and supply chain management. It is the process of scheduling components' delivery as soon as they have been ordered. It's important as it reduces leadtimes and increases throughput.