The Empire State Index provides a valuable indicator of regional manufacturing. It is a snapshot showing the state's current business climate. It is calculated by a survey of 200 manufacturers. The Federal Reserve Bank of New York sends out the survey each month to these manufacturers. An increase in New York's manufacturing industry is indicated by an index that is greater than zero. It indicates worsening circumstances, however, if the index is lower than zero.

The Empire State Manufacturing Index fell to a six-month low of minus 11.2 in December. This was the worst drop since March 2020. It also exceeded the Dow Jones economists median estimate, which was -35. The Empire State Index was negative at least five times in the three previous months.

Although the future general economic conditions index was in the high 20s for many months, it actually fell to negative 6.2. However, the index is still much higher than that of the ISM manufacturing index.

In July, the Empire State Index climbed to 43 points. This was the first time the index has risen above the 33-point mark in eight years. Despite the rise in the index, it has been volatile, with several weaker readings in recent weeks.

The index is calculated using 11 indicators, including new orders, capital expenditures, and the number of employees. Overall, these numbers indicate an increase in New York State’s manufacturing industry.

The Empire State Index is also useful in indicating inflationary pressures. While prices paid in the manufacturing industry increased, inventories decreased. Inventories are an indicator of the health and well-being of the economy.

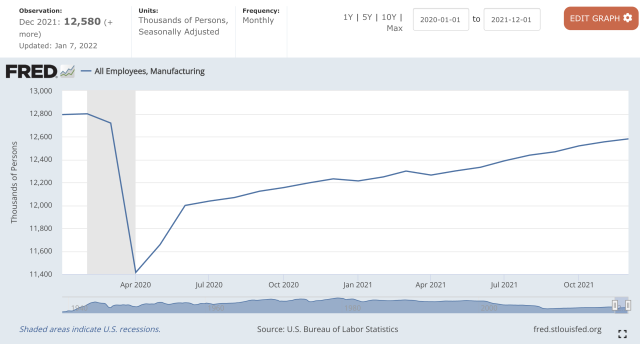

However, the Empire State Index has indicated a decline of employment. The number employed workers dropped to 7.4 from 8.2 in the previous two years. While employment levels aren’t an indicator or growth, the employment indicator is a good indicator to see how strong the labor market is.

For the past seven month, new orders have been in the positive column. But they are decreasing. The shipments indicator is still at 8.0. The range's low end is marked by the new orders and prices received indexes. It is better than the 0.3% prior shipments index but still falls short of Econoday consensus, which is minus 2.0.

Although the Empire State has not been above 34.0 since March 2006, it is still positive. This means that the index indicates that manufacturers expect to see some improvement over the next six months. The Empire State Manufacturing Index is more powerful than the CaixinPMI.

While the Empire State survey gives an accurate indicator of New York’s manufacturing industry's health, it is not a good predictor for the national ISM manufacturing score. This is due to the fact that the survey is based solely on the opinions a selected group of manufacturing executives. This means that the results of the survey don't have any biases based on a single industry.

FAQ

What is the job of a production plan?

A production planner ensures all aspects of the project are delivered on time, within budget, and within scope. They also ensure that the product/service meets the client’s needs.

What makes a production planner different from a project manger?

A production planner is more involved in the planning phase of the project than a project manger.

Why automate your warehouse

Modern warehouses are increasingly dependent on automation. E-commerce has increased the demand for quicker delivery times and more efficient processes.

Warehouses need to adapt quickly to meet changing needs. In order to do this, they need to invest in technology. Automating warehouses has many benefits. Here are some reasons why it's worth investing in automation:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Safety increases

-

Eliminates bottlenecks

-

This allows companies to scale easily

-

It makes workers more efficient

-

Gives you visibility into all that is happening in your warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

Quality products delivered on time

-

Eliminates human error

-

This helps to ensure compliance with regulations

What are the requirements to start a logistics business?

To be a successful businessman in logistics, you will need many skills and knowledge. Effective communication skills are necessary to work with suppliers and clients. You need to understand how to analyze data and draw conclusions from it. You will need to be able handle pressure well and work in stressful situations. In order to innovate and create new ways to improve efficiency, creativity is essential. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

It is also important to be efficient and well organized in order meet deadlines.

What is the best way to learn about manufacturing?

You can learn the most about manufacturing by getting involved in it. You can also read educational videos or take classes if this isn't possible.

Is there anything we should know about Manufacturing Processes prior to learning about Logistics.

No. You don't have to know about manufacturing processes before learning about logistics. Understanding the manufacturing process will allow you to better understand logistics.

How can excess manufacturing production be reduced?

Better inventory management is key to reducing excess production. This would reduce the time spent on unproductive activities like purchasing, storing and maintaining excess stock. This will allow us to free up resources for more productive tasks.

A Kanban system is one way to achieve this. A Kanban board, a visual display to show the progress of work, is called a Kanban board. Kanban systems allow work items to move through different states until they reach their final destination. Each state represents a different priority.

To illustrate, work can move from one stage or another when it is complete enough for it to be moved to a new stage. A task that is still in the initial stages of a process will be considered complete until it moves on to the next stage.

This allows you to keep work moving along while making sure that no work gets neglected. With a Kanban board, managers can see exactly how much work is being done at any given moment. This data allows them adjust their workflow based upon real-time data.

Another way to control inventory levels is to implement lean manufacturing. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Anything that does not contribute to the product's value is considered waste. Some common types of waste include:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Exceed materials

Manufacturers can increase efficiency and decrease costs by implementing these ideas.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to use 5S in Manufacturing to Increase Productivity

5S stands in for "Sort", the "Set In Order", "Standardize", or "Separate". Toyota Motor Corporation was the first to develop the 5S approach in 1954. It improves the work environment and helps companies to achieve greater efficiency.

This approach aims to standardize production procedures, making them predictable, repeatable, and easily measurable. It means tasks like cleaning, sorting or packing, labeling, and storing are done every day. This knowledge allows workers to be more efficient in their work because they are aware of what to expect.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step is a different action that leads to greater efficiency. Sorting things makes it easier to find them later. When you set items in an order, you put items together. After you have divided your inventory into groups you can store them in easy-to-reach containers. Make sure everything is correctly labeled when you label your containers.

Employees need to reflect on how they do their jobs. Employees must understand why they do certain tasks and decide if there's another way to accomplish them without relying on the old ways of doing things. In order to use the 5S system effectively, they must be able to learn new skills.

The 5S method increases efficiency and morale among employees. They are more motivated to achieve higher efficiency levels as they start to see improvement.