You have reached the right place if you are searching for a job within the manufacturing sector. With the introduction of new technology, the manufacturing industry is always evolving and improving. Although you might not have much experience in the field, it doesn't mean you have to have a college degree. A majority of major manufacturing companies offer on-the job training to help you learn the skills you need. Read on to learn more about the manufacturing jobs near me.

Operator of machines: Job description

To find a job as machine operator, you can download a job description sample. As a guide, you can modify the job description to fit your needs. Monster also has job listings. Your opening paragraph for a job description is your chance sell your company and your company to prospective employees. You should describe in just two to three words what makes you unique and why this position is right for you.

Operators of machines perform many tasks. They include loading and unloading parts, operating the machines, and even operating them. They also carry out routine maintenance checks and adhere to safety regulations. As part of a team, they may be responsible for maintaining equipment, supervising other operators, and conducting quality checks. Other duties may also be included in some job descriptions, such as helping warehouse operations. They are required to clean and inspect equipment after they have finished their work.

Manager of plastic injection mold operations

To be a manager of plastic injection molding operations, one must have the ability to oversee the entire process from beginning to end. The duties of this position include setting up new injection molding machinery and coordinating the processing of injection molding tooling. The candidate should also have experience in managing large projects, building relationships and coordinating engineering changes to existing programmes. To maximize efficiency, they should be able direct the activities in the plant.

A job description should detail the responsibilities of the position and its benefits. When possible, include operator qualifications and technical safety. Use action-oriented language, avoid abbreviations. Include details about the company's culture, social media presence, and other relevant information. These details will help to attract high-quality candidates. You should also include an employer's image and job description. A company's image is crucial to attracting qualified candidates.

Job description for an assembly line worker

Assemble products using a production machine. Assigned to a specific part of the product, assembly line workers must hand off the finished item to the next worker on the line. They manage the inventory and ensure product quality. Safety and health are important aspects of assembly line work. They must also be able to work in a clean environment.

It requires good hand-eye coordination and physical fitness. Assemblers can be exposed to chemicals and hazardous fumes. Assemblers must be careful with machinery and tools. Failure to do so can lead to serious injuries. This job requires speed and attention to detail. Assemblers should be able communicate with other members of the assembly line station and report any malfunctioning equipment or machinery.

Manufacturing jobs: Career opportunities

If you're in search of a new career, manufacturing is the perfect place to start. Manufacturing jobs range from production to design engineering, quality assurance, and program management. You can also become a quality inspector or manager as you progress in the industry. These roles are often rewarding, and there is a lot to be done. People with limited experience will find many opportunities in the industry. Manufacturing is a good career choice for recent grads, people who are looking to improve their work experience, and those who want a change in industries.

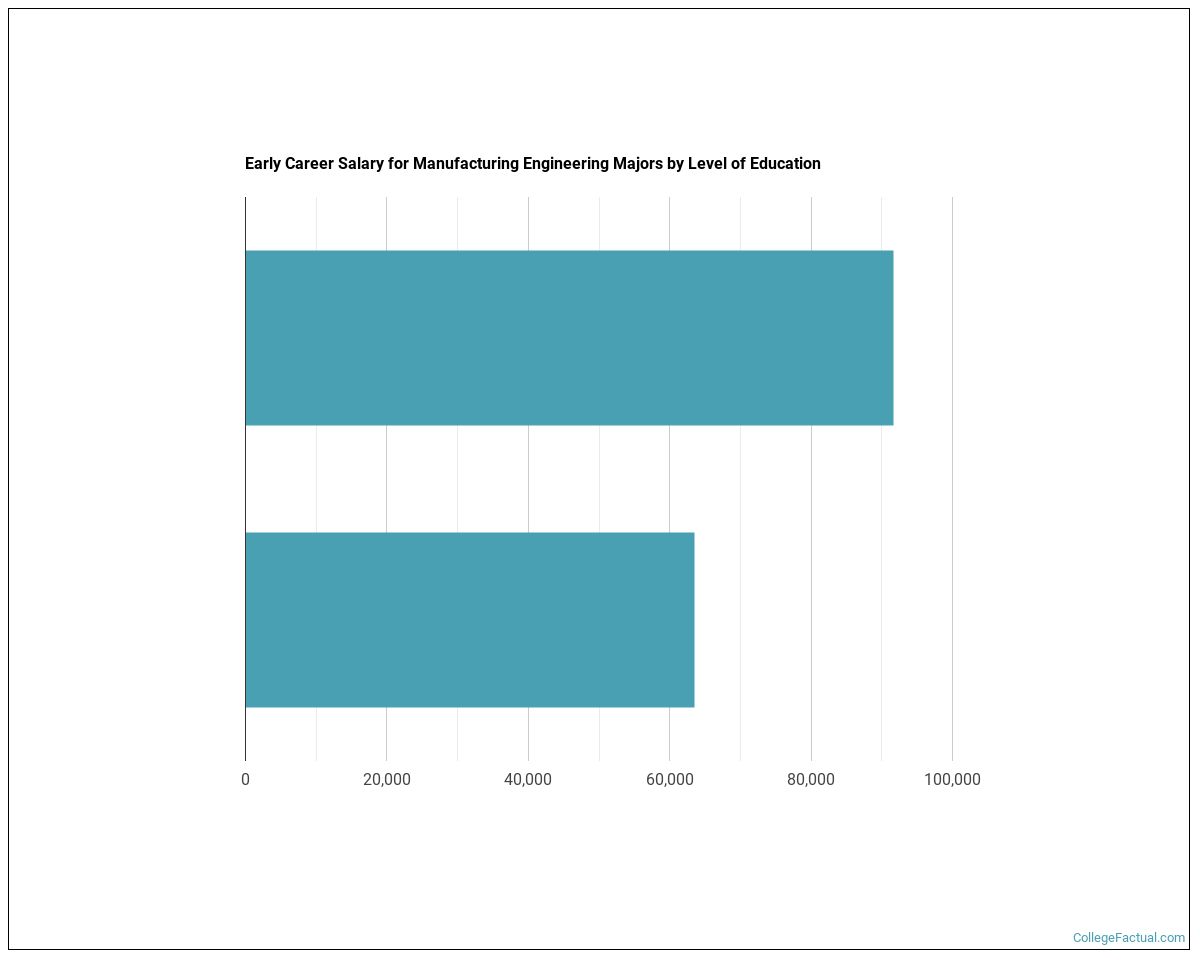

Manufacturing careers may be extremely lucrative. This field can help you get diverse opportunities in post-secondary education. To further your career, an apprenticeship can be pursued or you may enroll in a two-year or four year college. There are many options. Manufacturing careers are not for everyone.

FAQ

What does it mean to warehouse?

A warehouse is a place where goods are stored until they are sold. It can be an outdoor or indoor area. It could be one or both.

How can manufacturing prevent production bottlenecks?

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes both planning for capacity and quality control.

The best way to do this is to use continuous improvement techniques such as Six Sigma.

Six Sigma is a management system used to improve quality and reduce waste in every aspect of your organization.

It's all about eliminating variation and creating consistency in work.

What is production planning?

Production Planning is the creation of a plan to cover all aspects, such as scheduling, budgeting. Location, crew, equipment, props and other details. This document will ensure everything is in order and ready to go when you need it. It should also provide information about how best to produce the best results while on set. It should include information about shooting locations, casting lists, crew details, equipment requirements, and shooting schedules.

The first step is to decide what you want. You may already know where you want the film to be shot, or perhaps you have specific locations and sets you wish to use. Once you have identified the scenes and locations, you can start to determine which elements are required for each scene. You might decide you need a car, but not sure what make or model. To narrow your options, you can search online for available models.

After you have selected the car you want, you can begin to think about additional features. Do you have people who need to be seated in the front seat? Perhaps you have someone who needs to be able to walk around the back of your car. You might want to change your interior color from black and white. These questions will help guide you in determining the ideal look and feel for your car. Also, think about what kind of shots you would like to capture. What type of shots will you choose? Maybe you want the engine or the steering wheels to be shown. This will allow you to determine the type of car you want.

Once you've determined the above, it is time to start creating a calendar. You can create a schedule that will outline when you must start and finish your shoots. You will need to know when you have to be there, what time you have to leave and when your return home. So everyone is clear about what they need to do. You can also make sure to book extra staff in advance if you have to hire them. You should not hire anyone who doesn't show up because of your inaction.

Also, consider how many days you will be filming your schedule. Some projects are quick and easy, while others take weeks. While creating your schedule, it is important to remember whether you will require more than one shot per day. Multiple takes of the same location will lead to higher costs and take more time. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Budget setting is an important part of production planning. As it will allow you and your team to work within your financial means, setting a realistic budget is crucial. You can always lower the budget if you encounter unexpected problems. However, you shouldn't overestimate the amount of money you will spend. You will end up spending less money if you underestimate the cost of something.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

What is the difference between manufacturing and logistics

Manufacturing is the production of goods using raw materials. Logistics is the management of all aspects of supply chain activities, including procurement, production planning, distribution, warehousing, inventory control, transportation, and customer service. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

What is the difference between Production Planning and Scheduling?

Production Planning (PP), is the process of deciding what production needs to take place at any given time. Forecasting demand is one way to do this.

Scheduling refers to the process of allocating specific dates to tasks in order that they can be completed within a specified timeframe.

What does manufacturing industry mean?

Manufacturing Industries are businesses that produce products for sale. These products are sold to consumers. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. They create goods from raw materials, using machines and various other equipment. This includes all types of manufactured goods, including food items, clothing, building supplies, furniture, toys, electronics, tools, machinery, vehicles, pharmaceuticals, medical devices, chemicals, and many others.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

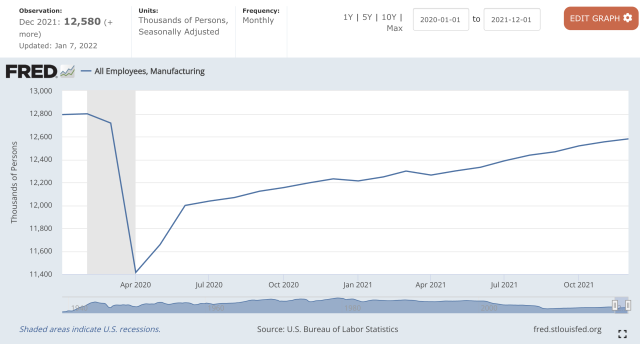

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

Six Sigma and Manufacturing

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." Motorola's Quality Improvement Department in Tokyo, Japan developed Six Sigma in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. Six Sigma aims to reduce variation in the production's mean value. You can calculate the percentage of deviation from the norm by taking a sample of your product and comparing it to the average. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding the dynamics of variability within your business is the first step in Six Sigma. Once you understand this, you can then identify the causes of variation. It is important to identify whether the variations are random or systemic. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. Random variations would include, for example, the failure of some widgets to fall from the assembly line. It would be considered a systematic problem if every widget that you build falls apart at the same location each time.

After identifying the problem areas, you will need to devise solutions. This could mean changing your approach or redesigning the entire process. After implementing the new changes, you should test them again to see if they worked. If they don't work, you will need to go back to the drawing boards and create a new plan.