The food manufacturing industry employs many professionals and managers. Top executives plan and manage production operations. Managers of industrial production oversee the day to day operations at a manufacturing plant. Marketing, community relations, sales, marketing and public relations managers direct the sales and promotional programs.

The food manufacturing industry has many jobs

New York has many jobs in food manufacturing. The top three occupations include bakers, food batchmakers, and packaging and filling machine operators. These occupations account for just half of the state's food manufacturing jobs. The state saw an increase in food manufacturing employment in seven of its 10 labor market areas.

The improving job market is also responsible for the increase in food production jobs. In February, the unemployment rate was 3.8%, the lowest level in more than a decade. The largest increase in food manufacturing employment was in the nondurable goods industry, with companies hiring 16,000 more workers.

Average wages for workers in the industry

The average wage for workers in food production is between $26,000 and $52,000 per a year. The highest paid earn an average $52,000 per a year. For those with more years of experience, the salary range is higher. But, the lowest 10% of earners earn less that $26,000 per annum. Food Factory Workers' salaries are not as high as other jobs in the manufacturing sector, but they are generally within the same range.

In the last few years, average wages have increased in this industry. The manufacturing industry is an integral part of our economy. However, it's not an isolated industry. Knowing how workers interact with other sectors of our economy is vital.

The locations that have the highest concentration of workers in the sector

2013 saw three New York State labor markets containing food manufacturing companies: the Finger Lakes region, the Southern Tier and Western New York. Combined, these three regions employed almost half the food manufacturing workforce. These regions had the highest average wages in Western New York, Southern Tier, Hudson Valley and Southern Tier.

Food processing is a highly skilled industry. Food manufacturing companies have difficulty finding skilled workers because of the lack of workers in certain areas. It is becoming increasingly difficult for companies to hire people to work in distribution trucks or other lower-level jobs. According to a recent survey by career site CareersInFood.com, the number of open roles in food manufacturing has increased 12% in the past year, with a 37% increase in the past 24 months.

There are approximately 12,000 workers in this industry.

According to the Bureau of Labor Statistics, the number of workers in the food manufacturing industry increased by 7.200 in February, a growth of over 1% from January. This month marks the third straight month of job gains for the industry, which is gradually recovering from many headwinds. The industry's employment has been affected by the COVID-19 pandemic and a labor shortage. According to the Bureau of Labor Statistics, the industry employed 40,700 people in February.

New York State's number of food processing firms grew by 8.8% between 2003-2013. Employment increased in four of the 10 labor market regions, with the largest increases in the Southern Tier and Hudson Valley.

FAQ

What does warehouse mean?

A warehouse or storage facility is where goods are stored before they are sold. You can have it indoors or outdoors. In some cases, it may be a combination of both.

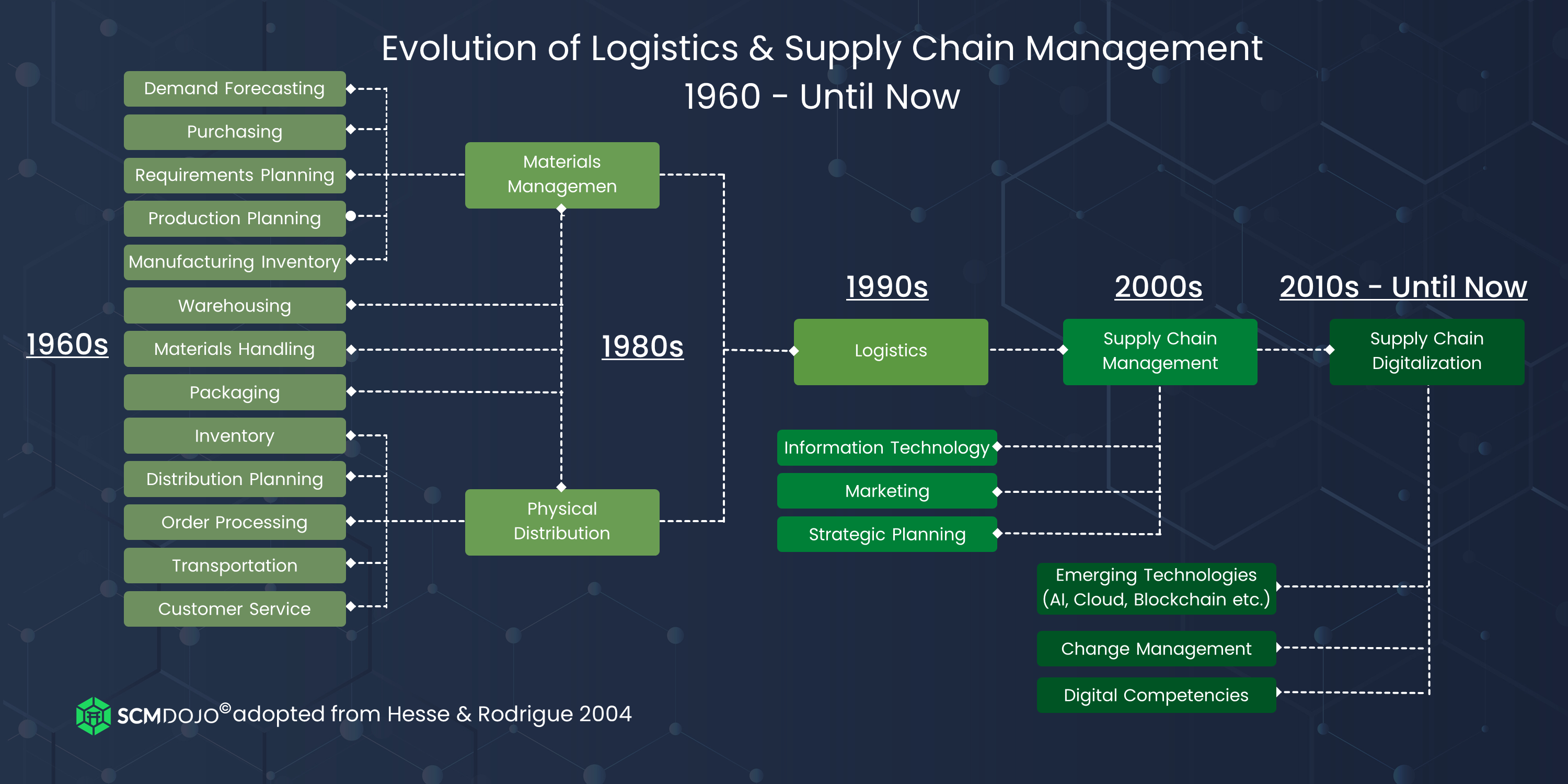

What is the difference between manufacturing and logistics

Manufacturing refers the process of producing goods from raw materials through machines and processes. Logistics is the management of all aspects of supply chain activities, including procurement, production planning, distribution, warehousing, inventory control, transportation, and customer service. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

What skills is required for a production planner?

To become a successful production planner, you need to be organized, flexible, and able to multitask. Communication skills are essential to ensure that you can communicate effectively with clients, colleagues, and customers.

What are the essential elements of running a logistics firm?

It takes a lot of skills and knowledge to run a successful logistics business. Effective communication skills are necessary to work with suppliers and clients. You must be able analyze data and draw out conclusions. You will need to be able handle pressure well and work in stressful situations. You need to be innovative and creative to come up with new ways to increase efficiency. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

It is also important to be efficient and well organized in order meet deadlines.

How can we improve manufacturing efficiency?

The first step is to identify the most important factors affecting production time. Then we need to find ways to improve these factors. If you don’t know how to start, look at which factors have the greatest impact upon production time. Once you have identified them, it is time to identify solutions.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to use 5S to increase Productivity in Manufacturing

5S stands for "Sort", "Set In Order", "Standardize", "Separate" and "Store". Toyota Motor Corporation developed the 5S method in 1954. It improves the work environment and helps companies to achieve greater efficiency.

This approach aims to standardize production procedures, making them predictable, repeatable, and easily measurable. This means that daily tasks such as cleaning and sorting, storage, packing, labeling, and packaging are possible. These actions allow workers to perform their job more efficiently, knowing what to expect.

Five steps are required to implement 5S: Sort, Set In Order, Standardize. Separate. Each step requires a different action, which increases efficiency. You can make it easy for people to find things later by sorting them. When you set items in an order, you put items together. After you have divided your inventory into groups you can store them in easy-to-reach containers. Finally, label all containers correctly.

This requires employees to critically evaluate how they work. Employees need to be able understand their motivations and discover alternative ways to do them. In order to use the 5S system effectively, they must be able to learn new skills.

The 5S method not only increases efficiency but also boosts morale and teamwork. They are more motivated to achieve higher efficiency levels as they start to see improvement.