Manufacturing jobs are more than just a job in the Capital Region. To get the best out of this industry, these jobs require high levels of education and training. The region's average annual income for a factory worker is $88,406, and this number is expected to rise by 2.5%. Numerous manufacturing companies have taken steps to ensure that workers are not exposed to safety and health hazards.

In fact, Texas' Capital Region has 30 percent of all manufacturing jobs in the state. Although the sector's number declined by -800 by February 2021 it was not a drop in employment. Acme Brick, Samsung Austin Semiconductor and Acme Brick are just a few of the innovative companies that can be found in this area. This is why the metroplex is one the most dynamic in the country.

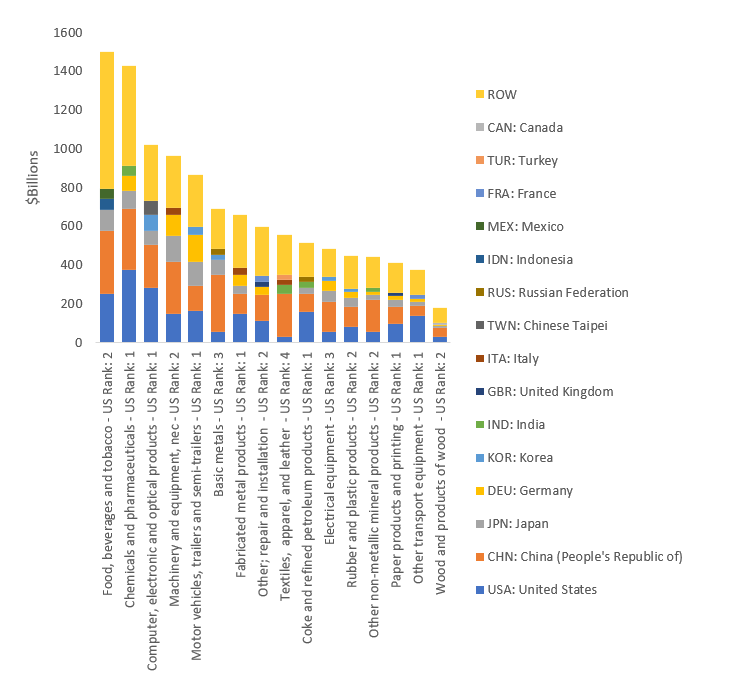

Texas Commission on Economic Opportunity has created a new interactive exhibit on this topic to highlight the Capital Region's manufacturing industry. It has a chart showing the area's manufacturing industries, as well a lot of useful information. One of the most attractive features is the "Essential Texas” mobile app. It allows visitors easy access to data on local tourism, business and the area's past. A virtual visitor’s center is another great feature. You can learn about the regions most important industries as well as how they benefit the local community.

While the interactive exhibit is certainly impressive, you will also want to check out other TCEO resources. Among them is the Capital Region of Texas, a comprehensive look at a swath of the state stretching from Llano to San Marcos. Here, you can find out how the region has managed to buck the national recession and how it has been able to keep up with new industries. You can also start a new career in the region, since it is home to many qualified and trained individuals. The options are endless, regardless of whether you are looking to work full-time or part time.

Several of the most prestigious companies in the technology industry are located in the area, including Apple, Dell, and Oracle. The capital city also houses Rhythm Superfoods - a natural and organic snack company. Manufacturing is exciting and diverse in the Capital Region.

The manufacturing sector of the capital is not a monopoly. Despite the aforementioned recession, the area has maintained a robust employment base, which has resulted in more than 65,000 manufacturing jobs in the region alone. These jobs pay quite a bit, and the country's manufacturing accomplishments are almost as impressive.

FAQ

What is the role of a production manager?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. A production planner ensures that the service and product meet the client's expectations.

Can certain manufacturing steps be automated?

Yes! Yes. The wheel was invented by the Egyptians thousands of years ago. Robots are now used to assist us in assembly lines.

There are many applications for robotics in manufacturing today. These include:

-

Automated assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Automation can be applied to manufacturing in many other ways. 3D printing is a way to make custom products quickly and without waiting weeks or months for them to be manufactured.

How can we improve manufacturing efficiency?

First, we need to identify which factors are most critical in affecting production times. The next step is to identify the most important factors that affect production time. If you don't know where to start, then think about which factor(s) have the biggest impact on production time. Once you identify them, look for solutions.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to Use Lean Manufacturing for the Production of Goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It is about eliminating defects and waste from all stages of the value stream. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing is widely practiced in many industries around the world. Toyota's philosophy has been a key driver of success in many industries, including automobiles and electronics.

Five principles are the basis of lean manufacturing:

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce waste - Stop any activity that isn't adding value to the supply chains.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many businesses are now using lean manufacturing to improve their competitiveness. Some economists even believe that lean manufacturing can be a key factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

Lean manufacturing can be applied to almost every aspect of an organization. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three main types in lean manufacturing

-

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This approach is designed to reduce lead times and increase the availability of components. It also reduces inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. You should repair any part that needs to be repaired during an assembly line. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous improvement involves continuous improvement of processes and people as well as tools.